Making small rivets

These are what I call 'spoon rivets'. Many people have the need to use small rivets, and these are sometimes hard to come by. Small brass nails work well, but these come in limited sized and are sometimes a bit pricy. Making small rivets is best done with a special jig that holds the wire securely on all sides to keep it from deforming while the head is being shaped. If you don't have one of these jigs it's a little difficult. Here is a way to create all the small rivets you want with no special tools. All you need is a teaspoon, a pair of pliers, and some standard copper electric wire.

Anyone who has tried to make a little rivet by clamping a piece of wire in a vice will note with some frustration at how the shaft usually bends over before the rivet head is completed.As any good metalsmith will tell you, light blows to a piece of metal will affect the surface metal, heavy blows move metal below the surface. We can use this to our advantage by using a standard stainless steel teaspoon as a hammer.

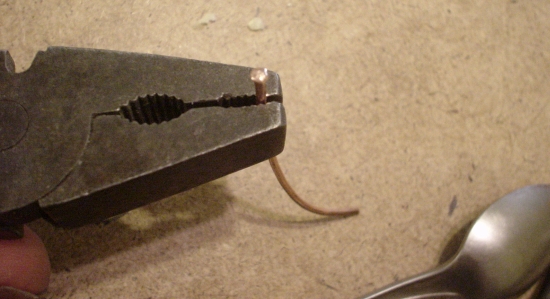

Hold a piece of copper wire in some pliers, leaving about 1/4" above the side as shown. You can aneal it first if you have a torch, but its not absolutely necessary. Use the back of the spoon to tap the head. It has just enough weight to move the surface or head of the wire without deforming the shaft. Light, repeating blows are all that is required. You will need to stop often and move the wire back up so the head is not resting on the side of the pliers. Holding the wire in a pair of pliers is all that is needed for support. Do not rest the pliers on anything, just hold them in your hand. We want all the energy that is not absorbed at the rivet head to be absorbed by the give of your hand, not the rivet shaft.

Making the head

After repeated tapping and repositioning of the wire you will see a mushroomed head starting to form. Continue to tap this out into a small half-round rivet head by tapping slightly off-center with the rounded back of the spoon.

This does not take a lot of force. We want whole lot of light blows, not a few heavy ones. Cut the rivet off the wire when finished.

This is not a medeival method, obviously, as many small rivets were cut from sheet as an elogated triangle and the head formed with a standard nail header. No one would have taken the time to draw out wire and then head it, however it is a simple, low-tech method of producing small rivets.